Wire Rope Sheave Groove Design

Pulleys with two grooves are for use where multiple pulleys move a single load such as block and tackle systems.

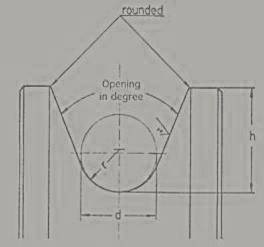

Wire rope sheave groove design. Angle must be restricted where the wire rope passes over the lead or fixed sheave and onto a drum. The radius at the bottom of the groove should be slightly larger than the rope. Since the wire rope is hard the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. This provides for better rope support.

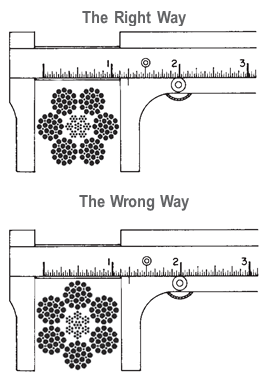

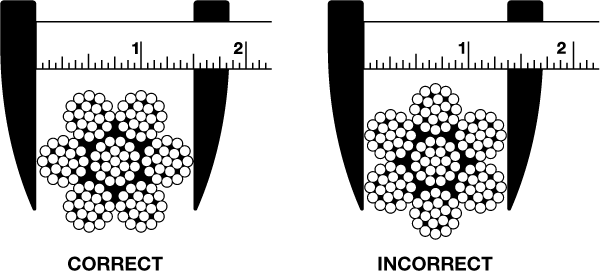

Performance of wire rope in a machine is affected by design of its sheaves and drums. The hardness of sheaves is a factor that is often overlooked. To avoid this ensure your steel cable sheaves are flame hardened. G 1 05 r 2 g groove radius r rope diameter typically the groove angle is 30.

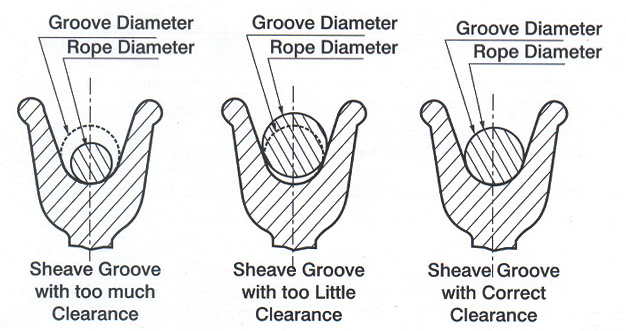

15 pulley or sheave. Hang these pulleys from hooks screws and bolts to assist with horizontal pulling or to guide a rope. If the groove is too small the rope will be pinched as it is forced into the groove under the influence of load thus damaging both the rope and the sheave. If the groove is too large there could be insufficient.

Regardless of what your industry calls it it s a wheel with a groove that is designed to support movement and change the direction of force in a wire rope or belt. Groove design the groove depth should be at least 1 75 times the rope diameter. Wire rope and cable products. A simple way to determine if your grooves are worn out.

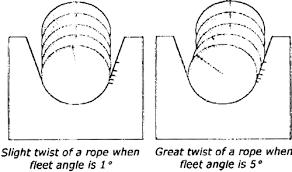

Ensure sheave groove hardness. The angle should not exceed 1 1 2 for a smooth drum not 2 for a grooved drum. The useful lifetime of wire rope is mostly determined by fatigue hertzian pressure between wire rope and sheave and external conditions such as line pull sheave diameter groove profi le and sheave material. In contrast to most other machine components wire rope must be replaced before it fails.

They have a bracket on the bottom for tying off one end of your wire rope. Groove dimensions for optimum rope life the sheave groove profile should be correctly matched to the rope diameter d r. Wire rope and sheave life through changes to the sheaves and addresses the superintendent who says they don t make ropes like they used to and i ve never ever had to regroove a sheave rope performance groove types the u groove sheave the u groove sheave found predominantly in older installations is the sheave of choice for. Performance of wire rope in a machine is affected by design of its sheaves and drums.

They require about half the force of a single groove pulley to move the same load. Excessive fleet angle results in abrasion between the rope and sheave groove flange and also be tween adjacent turns of the rope as it spools on and off the drum.