Wire Rope Sheave Design Manual

Light weight nylatech sheaves are 1 8th the weight of steel or iron sheaves.

Wire rope sheave design manual. This improves the. Rope dia pd ratio 18 1 od pd ratio 24 1 od 1 4 4 1 2 5 1 8 6 6 5 8 3 8 6 3 4 7 11 16 9 9 15 16. Choose from our selection of rope sheaves including over 250 products in a wide range of styles and sizes. In general these ropes are used as single part lines or in situations where operating conditions require a rope that will resist cabling in a multipart system.

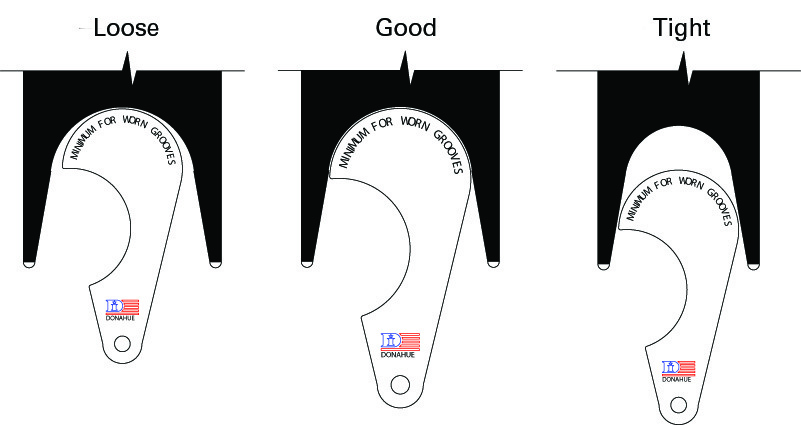

In contrast to most other machine components wire rope must be replaced before it fails. The following table will assist in determining the pitch diameter and outer diameter of the sheave. Wire rope sheaves is our primary business. 1 and a minimum fd of 3 5 for live or running wire ropes.

They require about half the force of a single groove pulley to move the same load. Ansi standards specify a minimum dp dr of 18. In stock and ready to ship. Wire rope sheave assembly single sheave block 250 dia.

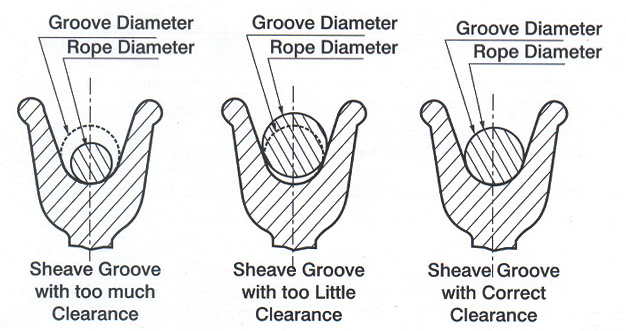

Since the wire rope is hard the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To obtain any of the wrtb publications warning tags sheave gauges or the astm standard specification for wire rope please contact wrtb fulfillment at 816 676 0811 or print out an order form that can be obtained on this site. The hardness of sheaves is a factor that is often overlooked. Wire rope sheave assembly single sheave block 200 dia general arrangement.

Due to their design and construction they are normally used for small diameters. We have the capability to manufacture your wire rope sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory of wire rope sheaves. To avoid this ensure your steel cable sheaves are flame hardened. Download cad dwg 0 56 mb.

They have a bracket on the bottom for tying off one end of your wire rope. Sheaves model a with bronze bushing. Industry standards identify the sheave pitch to rope diameter ratio dp dr and the design factor fd as important variables in the safe design of load bearing crane sheave applications. Rotation resistant wire rope is a special category class of wire rope designed to resist the tendency to spin or rotate under load.

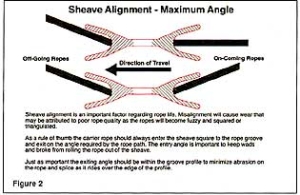

Hang these pulleys from hooks screws and bolts to assist with horizontal pulling or to guide a rope. Ensure sheave groove hardness. We consistently pride ourselves on our many years of customer service quick delivery and a quality product at a competitive price and wire rope sheaves. In order to extend wire rope life sheaves or.

Pulleys with two grooves are for use where multiple pulleys move a single load such as block and tackle systems.