Wire Harness Assembly Line

With so many models and variations schleuniger can provide the right assembly line for your exact requirements.

Wire harness assembly line. Product assembly is made by moving between working areas via a conveying canvas. 3different presets 1 to4m min. It offers a small footprint with operator access from both sides of the line saving valuable floor space and improving productivity. The eq line was designed based on the start stop principle.

In addition to the industry standard floor type wire harness assembly lines schleuniger offers space saving transverse type and horizontal lifting type solutions. A wire harness is an assembly of wires cables and connectors that transmit electric power or signals. Complete on site services include cutting stripping crimping soldering as well as the assembly of wires in a wide range. A wire harness assembly maximizes efficiency by binding wires together in a safe and secure routing pattern with the use of wire management products has as tie wraps pvc slit loom tubing and a wide range of sleeving.

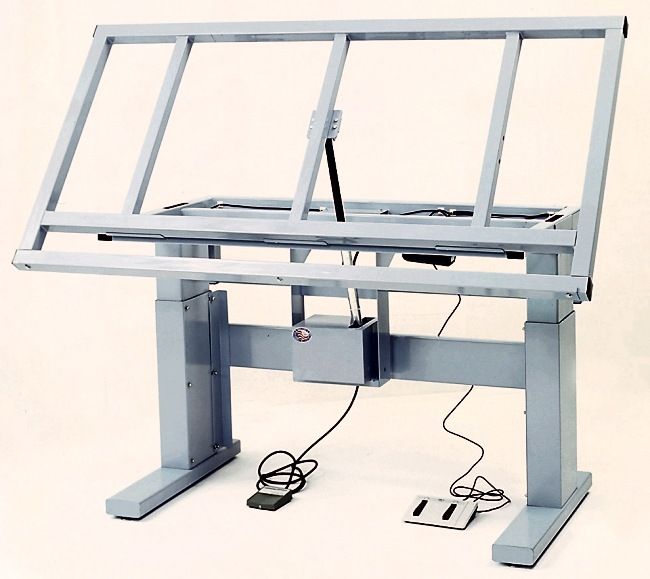

This line offers great benefits from the ergonomic point of view as it allows the front loading of components by operators. Trays move the wire harness assembly boards in a controlled way throughout the line and working areas. Horizontal or lifting type assembly lines offer a stable and efficient platform for wire harness assembly. The lifting type assembly line is divided into upper and lower levels.